TECH

Android System Intelligence: Smarter Tech Behind the Scenes

Android System Intelligence brings together on‑device AI, machine learning models, and predictive algorithms to create a seamless user experience. In the modern era of smartphones, it quietly optimizes everything from smart replies in your messaging app to adaptive battery management—all while maintaining user privacy and performance

What Is Android System Intelligence?

At its core, Android System Intelligence is an integrated suite of intelligent features built into Android OS. These include but aren’t limited to:

- On‑Device Machine Learning: Models embedded in your phone that analyze app usage, keyboard patterns, and touchscreen behavior without needing to send data to external servers.

- Contextual Awareness: The system’s ability to sense when motion, location, or app context signals that you might need a particular action—such as switching to Bluetooth when entering the car.

Core Features Powered by AI and ML

Smart Replies and Predictive Text

pronouns, and sentiment detection, Android System Intelligence suggests context‑appropriate replies in messaging apps. This accelerates communication while reducing cognitive load. The system even personalizes suggestions based on writing style.

Adaptive Battery and Performance Optimization

By applying machine learning to monitor resource usage patterns, the system intelligently throttles CPU frequencies, restricts background activities, and optimizes battery life based on your daily habits. Predictive analytics help ensure that the phone is ready to go when you are.

Contextual Suggestions and Shortcuts

Using contextual signals—time of day, geofencing, and user activity—the OS offers location‑based actions. For example, it might suggest “Navigate home” on a Tuesday afternoon after work or “Share ride” as you head to the airport. These predictive shortcuts use semantic understanding of intent, generated by underlying ML frameworks.

Live Caption and Transcription

on‑device speech recognition models, the system provides real-time captioning for calls, videos, and podcasts—even when you’re offline. It identifies spoken words, phonemes, and contexts to accurately render text captions.

Smart Actions in Notifications

From flight boarding pass alerts to appointment reminders, the system identifies entities like dates, airlines, and locations to make notifications actionable. With a single tap, users can add events to calendars, open maps, or initiate rideshare apps.

Privacy, Security, and On‑Device Intelligence

Data Protection with Federated Learning

technique in Android System Intelligence is federated learning—a privacy‑preserving way of training models using collective data patterns without transmitting personal content off the device. It aggregates updates to improve the base model, all while keeping raw data local.

Encrypted Processing and Safety Nets

Sensitive operations such as speech transcription and contextual prediction happen in secure isolated environments. Android’s sandboxing mechanisms ensure that malicious apps can’t interfere with the System Intelligence framework, maintaining integrity and trust.

User Control and Transparency

Users have granular control over features like smart reply, app suggestions, and on‑device learning. Through privacy dashboards and toggles, you can inspect which NLP functionalities are active and can disable them if desired.

Technological Foundations

Natural Language Understanding (NLU)

Android System Intelligence detects topics, named entities (people, places, organizations), and intent in conversation threads. For example, when you receive “Let’s meet Thursday at 5,” it tags Thursday (temporal entity) and 5 PM (time entity) and prompts a calendar entry.

Deep Neural Networks (DNNs)

These on‑device models are trained to recognize user patterns, classify app behavior, and predict likely actions. Quantization and pruning techniques reduce model size without significant accuracy loss, enabling smooth runtime performance.

Semantic Context Modeling

With semantic analysis, the system understands relationships like “lunch with Sarah” vs. “launch app Sarah.” This word sense disambiguation prevents erroneous actions and improves reliability in real‑world conversations.

Real‑World Use Cases

Improved Typing Efficiency

Autocorrect accuracy, emoji suggestions, and multi‑language typing are all handled by intelligent keyboards that learn your style and contextual word sequences. This reduces typos and accelerates messaging.

Location‑Based Automations

“Do Not Disturb” can be triggered automatically when you arrive at a work location. Contextual triggers like entering a gym or church can silence calls, based on recognized place entities.

Voice‑Assisted Workflows

Voice commands like “Hey Google, remind me to stretch in 30 minutes” use intent detection and scheduled event parsing.

Accessibility Enhancements

Live Transcribe, Select to Speak, and TalkBack rely on speech recognition, language models, and voice synthesis to assist users with hearing or visual impairments—making interactions more inclusive.

The Future: Smarter, Leaner, World‑Aware

Zero‑Touch AI Experiences

Future iterations of Android System Intelligence aim to make smart features more proactive. Predictive dialing, conversation summarization, and scheduling suggestions before you even think of them may soon be standard.

Cross‑Device Cognition

Whether on your phone, tablet, or wearable, intelligence features will synchronize learning signals—such as sleep patterns or fitness data—using secure tokenized transfer. This will enable holistic contextual insights.

Multimodal Understanding

Combining voice, gaze, gestures, and location data, the system will interpret user intent from multiple sensory inputs. For instance, a glance at your watch followed by a voice prompt could trigger workflow automation.

Frequently Asked Questions (FAQs)

Q1: How does Android System Intelligence protect user privacy?

Android uses federated learning and on‑device processing to keep personal data local, encrypts models and computations, and provides transparency controls that let you disable or modify smart features.

Q2: What types of machine learning models are used?

Models are typically deep neural networks optimized via quantization and pruning for efficient on‑device performance, with pipelines for speech recognition, intent parsing, and contextual classification.

Q3: Can I turn off features like Smart Reply or Adaptive Battery?

Yes—Android’s settings include privacy dashboards and toggles for each intelligent feature. You can disable smart suggestions, notifications optimization, or performance adjustments at will.

Q4: Does this intelligence drain battery?

The system uses low‑power hardware, such as Neural Processing Units (NPUs), and optimized ML frameworks. While intelligence features are active, the overall impact is minimal and often outweighed by battery‑saving optimizations.

Q5: Will Android System Intelligence work on older phones?

Many features are exclusive to newer silicon (e.g., Tensor chips), but core capabilities like Smart Reply and adaptive brightness exist on a wide range of devices—even those without specialized AI accelerators.

Conclusion

Android System Intelligence truly is “smarter tech behind the scenes.” By cleverly blending natural language understanding, contextual awareness, and on‑device machine learning, it delivers helpful suggestions and seamless automations tailored to your everyday life. As privacy protections like federated learning and encryption keep your data secure, these features continue to evolve—ushering in a future where your device understands, adapts, and assists without extra effort

TECH

Soft Copy Meaning: Powerful Digital Advantage

Soft Copy Meaning refers to any document, image, or file that exists in a digital format. Unlike a hard copy, which is a physical printout you can touch and hold, a soft copy is stored electronically—on your computer, smartphone, tablet, or in the cloud.

Why does this matter? Because soft copies are the backbone of modern communication, collaboration, and record-keeping. Whether you’re emailing a contract, sharing a presentation, or submitting an assignment, you’re almost always dealing with a soft copy.

What Is a Soft Copy? The Simple Definition

What is a soft copy? It’s a digital version of any document or file. This could be:

- A Word document saved on your laptop

- A PDF emailed to your boss

- A photo stored on your phone

- An eBook downloaded to your tablet

- A spreadsheet in Google Drive

If you can view, edit, or share it electronically, it’s a soft copy.

Soft Copy vs Hard Copy: What’s the Difference?

The debate of hard copy vs soft copy is as old as the personal computer. Here’s a quick comparison:

| Feature | Soft Copy | Hard Copy |

|---|---|---|

| Format | Digital (PDF, DOCX, JPG, etc.) | Physical (paper, printout) |

| Storage | Computer, phone, cloud | Filing cabinet, desk |

| Editing | Easy, unlimited | Requires reprinting |

| Sharing | Instant (email, cloud, USB) | Mail, hand delivery |

| Eco-friendly | Yes (no paper used) | No (uses paper/ink) |

| Security | Can be encrypted, password-protected | Can be locked away |

In 2025, soft copies are the default for most businesses, schools, and even government agencies.

Real-World Example: Soft Copy in Action

A job seeker recently shared,

“I used to print out dozens of resumes for every interview. Now, I just email a soft copy or upload it to the company’s portal. It’s faster, cheaper, and I can update it anytime.”

This shift from hard copy to soft copy is happening everywhere—from job applications to legal contracts and beyond.

Why Are Soft Copies So Popular in 2025?

Several trends have made soft copies the standard:

- Remote work: Teams need to share and edit documents from anywhere.

- Cloud storage: Services like Google Drive and Dropbox make it easy to store and access files.

- Sustainability: Reducing paper use is good for the planet and your budget.

- Speed: Soft copies can be sent, received, and updated in seconds.

Types of Soft Copies: More Than Just Documents

When people think of soft copies, they often picture Word docs or PDFs. But the term covers a wide range of digital files:

- Text files: DOCX, TXT, PDF

- Spreadsheets: XLSX, CSV, Google Sheets

- Presentations: PPTX, Google Slides

- Images: JPG, PNG, GIF

- Audio/Video: MP3, MP4, WAV

- eBooks: EPUB, MOBI, PDF

If it’s digital, it’s a soft copy.

How to Create a Soft Copy

Creating a soft copy is easier than ever:

- Type it: Use a word processor, spreadsheet, or presentation tool.

- Scan it: Use a scanner or your phone’s camera to digitize paper documents.

- Download it: Save files from the internet or cloud services.

- Convert it: Use apps to turn photos or scans into PDFs or other formats.

How to Share a Soft Copy

Sharing a soft copy is simple and fast:

- Email: Attach the file and hit send.

- Cloud link: Share a Google Drive, Dropbox, or OneDrive link.

- Messaging apps: Send files via WhatsApp, Slack, or Teams.

- USB drive: For offline sharing, copy the file to a flash drive.

Soft Copy Security: Risks and Best Practices

While soft copies are convenient, they come with security risks:

- Unauthorized access: Files can be hacked or shared without permission.

- Data loss: Accidental deletion or hardware failure can wipe out files.

- Phishing: Malicious files can be disguised as soft copies.

Best practices:

- Use strong passwords and encryption.

- Back up important files regularly.

- Be cautious with email attachments and downloads.

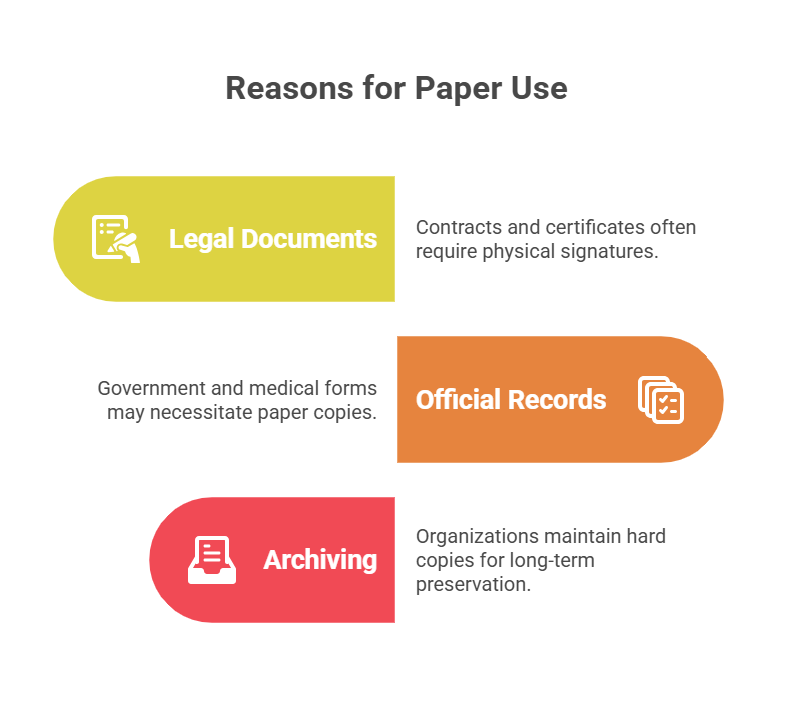

Hard Copy vs Soft Copy: When Do You Still Need Paper?

Despite the rise of soft copies, there are times when a hard copy is still required:

- Legal documents: Some contracts or certificates need a physical signature.

- Official records: Certain government or medical forms may require paper.

- Archiving: Some organizations keep hard copies for long-term storage.

But even in these cases, a soft copy is often created first and then printed as needed.

Soft Copy in Education: The New Normal

In schools and universities, soft copies have transformed learning:

- Assignments: Students submit essays and projects online.

- E-books: Textbooks are now digital, saving money and weight.

- Collaboration: Group projects happen in Google Docs or Microsoft Teams.

A teacher shared,

“I can grade assignments from my tablet, leave comments, and return soft copies instantly. No more lost papers or late submissions.”

Soft Copy in Business: Efficiency and Flexibility

Businesses rely on soft copies for:

- Contracts and proposals: E-signatures make deals faster.

- Invoices and receipts: Digital records are easier to track and audit.

- Reports and presentations: Teams can collaborate in real time.

Soft Copy in Government and Healthcare

Even traditionally paper-heavy sectors are going digital:

- E-filing: Tax returns, permits, and applications are now online.

- Medical records: Patient files are stored and shared as soft copies, improving care and reducing errors.

Pros and Cons of Soft Copies

Pros

- Easy to edit and update

- Instant sharing and collaboration

- Eco-friendly and cost-effective

- Secure (with proper precautions)

- Takes up no physical space

Cons

- Requires devices and internet

- Vulnerable to hacking or data loss

- May not be accepted for all legal purposes

- Can be accidentally deleted or overwritten

Soft Copy Meaning in 2025: The Future Is Digital

Looking ahead, soft copies will only become more important:

- AI-powered search: Instantly find any document, image, or file.

- Blockchain verification: Ensure authenticity and prevent tampering.

- Universal e-signatures: Make soft copies legally binding worldwide.

- Augmented reality: View and interact with soft copies in 3D.

FAQs

Q. What is a soft copy?

A. soft copy is a digital version of a document, image, or file that can be viewed, edited, and shared electronically

Q. How is a soft copy different from a hard copy?

A. soft copy exists in digital form (like a PDF or Word doc), while a hard copy is a physical printout on paper.

Q. Can a soft copy be printed?

A. Yes! You can print a soft copy to create a hard copy whenever needed.

Q. Are soft copies secure?

A. Soft copies can be secure if you use strong passwords, encryption, and regular backups. Always be cautious with sharing and storing sensitive files.

Real-Life Example: Soft Copy Saves the Day

A small business owner lost her laptop to a coffee spill. Luckily, all her invoices and contracts were saved as soft copies in the cloud. She accessed them from her phone and kept her business running without missing a beat.

How to Organize and Manage Soft Copies

- Use folders and clear naming conventions

- Back up files to the cloud and an external drive

- Regularly delete outdated or duplicate files

- Use document management software for large collections

Hard Copy vs Soft Copy: Which Is Better?

For most uses in 2025, soft copies win on speed, convenience, and sustainability. But for legal, archival, or official purposes, hard copies still have their place.

Final Thoughts

Understanding soft copy meaning is essential in our digital world. From job applications to medical records, soft copies are everywhere—and knowing how to create, share, and secure them is a must-have skill.

TECH

Boost Your Security with Door Peephole Cameras: Top 3 Benefits

Have you ever wondered if your home’s security is truly up to par? With the rise of smart technology, the door peephole camera has become a must-have for anyone serious about safety. Whether you live in a bustling city apartment or a quiet suburban home, knowing who’s at your door—without opening it—offers peace of mind that’s hard to beat.

But what exactly makes a door peephole camera so effective? And how do you choose the right one for your needs in 2025? Let’s dive into everything you need to know, from the basics to the latest innovations.

Why a Door Peephole Camera is a Game-Changer

Traditional peepholes have been around for decades, but they come with limitations. You have to be physically present, and the view is often limited or distorted. Enter the door peephole camera—a modern solution that combines convenience, security, and smart features.

Imagine being able to see, record, and even communicate with visitors from your smartphone, no matter where you are. That’s the power of today’s peepholecams.

User quote:

“I travel a lot for work, and my peepholecam lets me check on my apartment anytime. It’s like having a security guard in my pocket.”

What is a Door Peephole Camera?

A door peephole camera is a compact device that replaces or enhances your traditional peephole. It captures video footage of anyone at your door and often includes features like motion detection, night vision, and two-way audio.

Some models, like the popular peepholecam, are designed specifically for renters and apartment dwellers. They’re easy to install and don’t require drilling or permanent changes to your door.

Key Features to Look for in a Peep Hole Camera

When shopping for a peep hole camera, consider these essential features:

High-Definition Video

Clear video is crucial for identifying visitors. Look for cameras with at least 1080p resolution.

Wide-Angle Lens

A wide field of view ensures you can see packages, pets, and anyone lurking just out of sight.

Motion Detection

Smart motion sensors alert you to activity at your door, even if the visitor doesn’t ring the bell.

Night Vision

Infrared LEDs allow you to see clearly, even in total darkness.

Two-Way Audio

Speak to visitors or delivery drivers without opening the door.

Easy Installation

Many peepholecams are designed for DIY installation, making them perfect for apartments.

Peepholecams vs. Traditional Door Cameras

You might be wondering: what’s the difference between a peepholecam and a standard door camera for apartment use?

- Peepholecams are typically smaller and designed to fit into existing peepholes.

- They’re less invasive, making them ideal for renters.

- Many models are battery-powered, so there’s no need for wiring.

On the other hand, traditional door cameras may require more installation work but often offer additional features like integrated doorbells or smart locks.

The Best Door Camera for Apartment Living

If you live in an apartment, security can be tricky. You want to protect your space without violating building rules or annoying your neighbors. That’s where a door camera for apartment use shines.

Look for models that:

- Don’t require drilling or permanent installation

- Offer cloud storage or local SD card recording

- Have discreet designs that blend in with your door

Real-life example:

A renter shared, “My landlord was fine with my peepholecam because it didn’t damage the door. Now, I feel safer, and my neighbors are thinking about getting one too!”

How to Install a Door Peephole Camera

Most modern door peephole cameras are designed for easy installation. Here’s a quick overview:

- Remove the existing peephole (if you have one).

- Insert the camera through the hole.

- Secure the device with the included hardware.

- Connect to Wi-Fi and set up the app on your phone.

No special tools or wiring required! If you’re unsure, many brands offer step-by-step video guides.

Privacy and Security: What You Need to Know

With any smart device, privacy is a top concern. Here’s how to keep your peep hole camera secure:

- Change default passwords immediately.

- Enable encryption if available.

- Regularly update firmware to patch security vulnerabilities.

- Review app permissions and only grant what’s necessary.

Pros and Cons of Door Peephole Cameras in 2025

Pros

- Enhanced security: See who’s at your door anytime, anywhere.

- Easy installation: Perfect for renters and homeowners alike.

- Smart features: Motion alerts, night vision, and two-way audio.

Cons

- Battery life: Some models need frequent charging.

- Wi-Fi dependency: No internet means no remote access.

- Privacy risks: As with any smart device, there’s a risk of hacking if not properly secured.

The Evolution of Peepholecams: What’s New in 2025?

The latest peepholecams are smarter than ever. Expect features like:

- AI-powered facial recognition

- Integration with smart home systems

- Cloud-based video storage with advanced encryption

- Voice assistant compatibility

These innovations make it easier than ever to keep your home safe and connected.

Real-World Uses: How People Are Using Door Peephole Cameras

From busy parents to frequent travelers, people are finding creative ways to use their door peephole cameras:

- Package delivery monitoring

- Checking on kids or elderly relatives

- Deterring porch pirates and unwanted solicitors

- Documenting suspicious activity for building management

FAQs

1. How does a door peephole camera work?

A door peephole camera replaces your traditional peephole, capturing video and sending it to your phone or a monitor. Many models offer motion detection and two-way audio.

2. Are peepholecams easy to install in apartments?

Yes! Most peepholecams are designed for renters and require no drilling or permanent changes.

3. Can I use a door camera for apartment security without Wi-Fi?

Some models offer local recording, but most smart features require Wi-Fi for remote access and alerts.

4. What’s the difference between a peep hole camera and a traditional doorbell camera?

Peep hole cameras are smaller, fit into existing peepholes, and are less invasive—making them ideal for apartments and rentals.

Final Thoughts

In 2025, the door peephole camera is more than just a gadget—it’s a smart investment in your safety and peace of mind. Whether you’re a renter, homeowner, or just someone who values privacy, there’s a model out there for you.

TECH

What Does a Transistor Do? Discover Its Powerful Role

What Does a Transistor Do? transistor is a tiny electronic switch or amplifier. It controls the flow of electrical current in a circuit, turning signals on or off, or making them stronger. This simple function is the foundation of all modern electronics—from your phone’s processor to the memory in your laptop.

User quote:

“I used to think transistors were just for engineers, but once I learned what a transistor does, I realized they’re the reason my phone, TV, and even my car work!”

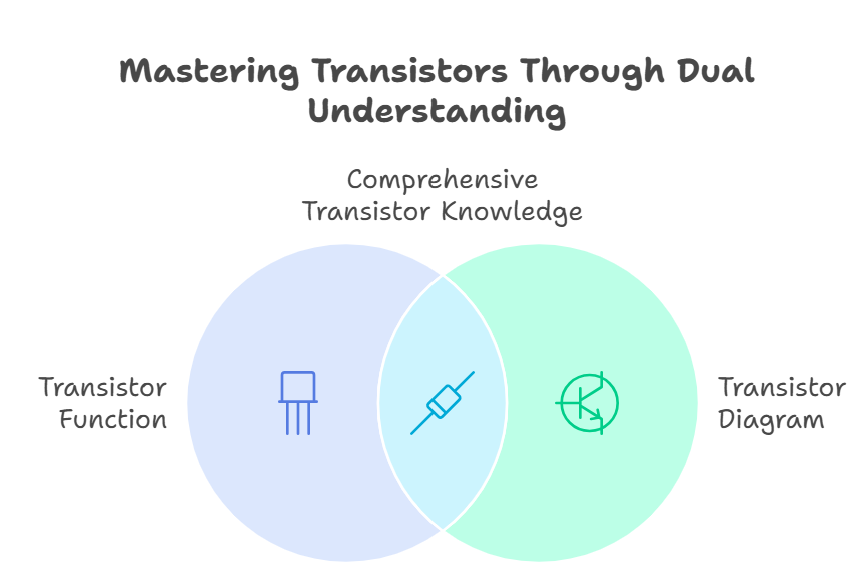

The Transistor Symbol: Decoding Circuit Diagrams

If you’ve ever looked at a circuit diagram and wondered what those odd shapes mean, you’ve probably seen the transistor symbol. There are two main types of transistors: bipolar junction transistors (BJT) and field-effect transistors (FET). Each has its own symbol:

- BJT: Looks like a circle with three lines (emitter, base, collector) and an arrow.

- FET: A straight line with three connections (source, gate, drain) and a T-shaped symbol.

Understanding the transistor symbol is key to reading schematics and building your own circuits.

What Does a Transistor Do in a Circuit?

Transistors have two main jobs:

1. Acting as a Switch

A transistor can turn a current on or off, just like a light switch. In computers, billions of transistors work together to represent 1s and 0s—the language of digital logic.

2. Acting as an Amplifier

Transistors can also make weak signals stronger. This is how your phone’s microphone picks up your voice and sends it loud and clear to the other end.

What Does a Tdiagram Transistorransistor Do? (And Why the Confusion?)

You might have seen the phrase what does a tdiagram transistorransistor do floating around online. It’s a typo or a mashup of “transistor diagram” and “what does a transistor do.” But it’s a good reminder: understanding both the function and the diagram of a transistor is crucial for anyone learning electronics.

How Many Transistors in a CPU? (Prepare to Be Amazed)

One of the most mind-blowing facts about modern technology is how many transistors in a CPU. In 2025, a single high-end processor can have over 100 billion transistors packed into a chip smaller than your fingernail. That’s more switches than there are people on Earth—by a factor of ten!

This incredible density is what makes today’s computers, smartphones, and AI systems so powerful.

The Evolution of the Transistor: From Radios to AI

Transistors were invented in 1947, replacing bulky vacuum tubes. Early radios had just a handful of transistors. Today, your smartwatch has more computing power than the computers that sent astronauts to the moon—all thanks to the relentless miniaturization of transistors.

Real-World Example: Transistors in Everyday Life

Think about your morning routine. Your alarm clock, coffee maker, and smartphone all rely on transistors. When you unlock your phone, millions of transistors in the display, processor, and memory work together in a split second to show your notifications.

How Transistors Changed the World

Without transistors, there would be no laptops, no internet, no streaming music, and no electric vehicles. They’re the unsung heroes of the digital age.

Types of Transistors and Their Uses

1. Bipolar Junction Transistor (BJT)

Used in amplifiers, radios, and analog circuits.

2. Field-Effect Transistor (FET)

Common in digital circuits, computers, and memory chips.

3. MOSFET (Metal-Oxide-Semiconductor FET)

The workhorse of modern CPUs and memory.

How Do Transistors Work? (A Simple Explanation)

A transistor has three parts: input, control, and output. When a small current or voltage is applied to the control (base or gate), it allows a larger current to flow from input to output. This is how it acts as a switch or amplifier.

Transistor Symbol in Practice: Reading a Schematic

Let’s say you’re looking at a circuit diagram for a simple amplifier. You’ll see the transistor symbol connected to resistors and capacitors. The arrow shows the direction of current flow. Once you recognize the symbol, you can start to understand how the circuit works.

What Does a Transistor Do in a Computer?

In computers, transistors are the building blocks of logic gates. Billions of them work together to perform calculations, store data, and run software. Every time you open an app, stream a video, or play a game, you’re relying on transistors.

How Many Transistors in a CPU: The Numbers Keep Climbing

- 1970s: Thousands of transistors per chip

- 2000s: Millions per chip

- 2025: Over 100 billion per chip

This exponential growth is known as Moore’s Law, and it’s the reason technology keeps getting faster and more powerful.

Risks and Challenges: The Limits of Transistor Technology

As transistors get smaller, they become harder to manufacture and more prone to errors. Engineers are exploring new materials, 3D stacking, and even quantum transistors to keep progress going.

Pros and Cons of Transistors

Pros

- Tiny size: Enables compact, powerful devices

- Low power: Efficient and cool-running

- Fast switching: Billions of operations per second

Cons

- Complex manufacturing: Requires advanced technology

- Heat management: Billions of transistors generate heat

- Physical limits: Approaching the size of individual atoms

Transistors in 2025: What’s New?

- 3D transistors: Stacked layers for more power in less space

- AI-designed circuits: Machine learning helps optimize transistor layouts

- Flexible electronics: Transistors in wearable and bendable devices

How to Spot a Transistor in a Circuit

Look for the transistor symbol—a circle with three lines or a T-shaped symbol. It’s usually connected to other components like resistors and capacitors.

Real-World Example: A Tweet About Transistors

“Just learned that my phone has more transistors than the first supercomputers. Mind blown! #techfacts”

FAQs

Q. What does a transistor do in simple terms?

A. transistor acts as a switch or amplifier, controlling the flow of electricity in a circuit.

Q. What is the transistor symbol in a circuit diagram?

A. The transistor symbol is a circle with three lines (for BJT) or a T-shaped symbol (for FET), showing the connections and current flow.

Q. How many transistors in a CPU in 2025?

A. High-end CPUs in 2025 can have over 100 billion transistors, enabling incredible processing power.

Q. What does a tdiagram transistorransistor do?

A. This phrase is a typo, but it refers to understanding both the function and the diagram of a transistor in electronics.

Final Thoughts

Understanding what does a transistor do isn’t just for engineers. It’s the key to appreciating the technology that powers your life. From the transistor symbol in a circuit diagram to the staggering number of transistors in a CPU, these tiny devices are the foundation of the digital world.

-

TECH3 weeks ago

TECH3 weeks agoSoft Copy Meaning: Powerful Digital Advantage

-

BLOG1 month ago

BLOG1 month agoHeaven’s Touch: A Miracle Prayer for Healing

-

FASHION2 months ago

FASHION2 months agoStyle Your Tech: Custom HP Notebook Cover Skins for a Sleek Look

-

HEALTH2 months ago

HEALTH2 months agoHormone Health for Men: Signs, Solutions, and Staying Proactive

-

BLOG1 month ago

BLOG1 month agoHow to Support a Loved One Dealing With Anger Challenges

-

TECH2 months ago

TECH2 months agoBlue Android Phone: Single Camera Simplicity

-

BLOG2 months ago

BLOG2 months agoSending Audio on Signal: Quick Guide

-

TECH2 months ago

TECH2 months agoAndroid No SIM Error: Fast Fix Guide